| Model: | Paul 35 |

|---|---|

| Min. Order: | 9 Ton |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 1200 ton per month |

| Packing: | 20 kgs packed in a... |

| Delivery Date: | 30 days | Chemical Auxiliary Agent: | NBR 35 is PVC resin modifier agent |

|---|

NBR Powder For PVC Modification Agent

Shape: White Powder

Application: making window seal strip, Autombile rubber seal strip, Hood seal, door sell, PVC seal srtip,Rubber gasket,shoes, oil pipe, O-ring etc...

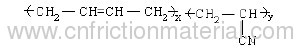

Composite:Acrylonitrile/Butadiene Copolymer,PVC

Function: Oil resistance,Soft

Grade: Excellent

Size: 0.98mm

Production Name Slight Cross-link Powdered Nitrile Butadiene Rubber(PNBR)

Chemical Structure

Product Index Appearance White or little yellow powder

Mooney Viscosity,ML100℃1+4 40-60

Acylonitrile Content,% 30-33

Sift Rate(0.90mm),% ≥98

Volatile,% ≤1

Basic Character

NBR Powder is high temperature polymerized, slight cross-linked arylontrile butadiene rubber which has low mooney viscosity and middle ACN content. It uses special technology of agglomeration into powder. It shows good resistance to oil, heat, cold and solvent. It also has good compression resistance, ageing resistance and convenient machining property.

Property Superiority

NBR Powder is good PVC resin modifier agent. It has very good compatibility with PVC resin. They can mix together in certain percentage.

NBR Powder can reach the machinery performance requirement of abroad similar products. It specially adapted in extrusive, injective and calendering goods.

Application

NBR Powder is mainly used in shoes, oil pipe, general gland strip, conveyor belt and so on.

Application Guidance

According to different usage and different demand, the dosage of NBR Powder is variable. When NBR Powder mix with PVC resin, and the PVC needs to be plasticated, the plastication temperature should be lower than 40℃, then add the NBR Powder and blend evenly. In the process of extrusion, we advice the process temperature be 120-170℃; In the process of calendering, we advice the process temperature be 150-170℃; In the process of injection, we advice the process temperature be 170-190℃.

Safe guidance

Except for good industrial operation directions, there is no special safe measure demanded. Please prevent dust formation and keep away from fire.

Package net weight is 20 kg/carton

Category: Bonding Agent